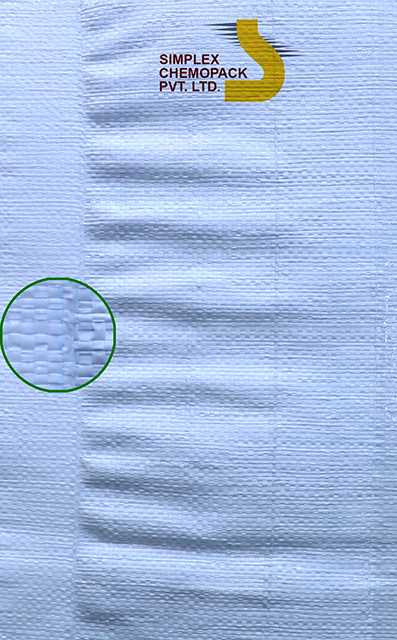

Sealed & Crush Fabric

In the innovative landscape of packaging solutions, Sealed Crush Fabric emerges as a noteworthy contender, offering a blend of strength, flexibility, and efficiency. This material has been refined through a meticulous process, ensuring it meets the exacting standards of various industries. Here’s a deep dive into what Sealed Crush Fabric is, its unique features, advantages, applications, specifications, and a final verdict on why it stands out as a choice for those in need of superior packaging solutions.

What is Sealed Crush Fabric?

Sealed Crush Fabric is engineered from polypropylene and undergoes a specialized heat-sealing process along its edges. This enhances both the fabric’s strength and its ability to form airtight seams during bag fabrication.

Sealed Crush Fabric is produced using a specialized approach that enhances the durability and functionality of polypropylene fabric bags. The core of its manufacturing process involves treating the edges of fabric pieces with heat to fuse them together without reaching the melting point of the material. This technique creates heat-fused seams or joints that retain at least 85% of the fabric’s original strength, negating the need for traditional sewing methods.

Features of Sealed Crush Fabric

- Exceptional edge strength: The heating process reinforces the fabric’s edges, ensuring maximum load-bearing capacity and reduced risk of tearing.

- Reliable sealing: Heat-fused seams create strong, leak-proof seals without the need for traditional stitching.

- Streamlined sewing: Even when sewing is required, the treated fabric allows for smoother, faster sewing with reduced risk of needle breakage.

- Flexibility and Durability: The sealed crush method endows the fabric with a robust yet bendable quality, making it suitable for handling heavy materials without sacrificing its shape or integrity.

Advantages of Using Sealed Crush Fabric

- Enhanced product protection: The robust construction and secure seals safeguard your products from damage and contamination.

- Improved handling: The strong fabric withstands the demands of filling, stacking, and transportation.

- Optimized production efficiency: Easier sewing and reduced machine downtime contribute to a streamlined manufacturing process.

- High Performance at Elevated Temperatures: The fabric is treated at temperatures ranging from 220 to 230°C, which enhances its mechanical properties, including tensile strength, abrasion resistance, and high-temperature endurance.

Applications of Sealed Crush Fabric

Sealed Crush Fabric finds its application across various sectors requiring durable and flexible packaging solutions. Its superior strength and temperature resistance make it ideal for packaging industrial goods like cement, where hot filling is part of the production line. Its adaptability and resilience also cater to the demands of sectors needing robust packaging that can withstand the rigors of transportation and storage.

- Heavy-duty bulk packaging: Ideal for materials like cement, aggregates, fertilizers, and chemicals.

- Agricultural products: Suitable for storing and transporting grains, seeds, and other similar goods.

- Other demanding applications: Adaptable to a range of industries requiring robust and securely sealed packaging.

Specifications to Consider

The specifications of Sealed Crush Fabric underscore its quality and performance:

- Temperature treatment between 220 to 230°C to enhance mechanical properties.

- Heat-fused seams that maintain 85% of the fabric’s original strength.

- Compatibility with high-speed stitching, minimizing mechanical breakdowns and production halts.

Final Verdict

Sealed Crush Fabric stands as a testament to innovation in the packaging industry, offering a blend of strength, flexibility, and efficiency that traditional materials struggle to match. Its unique manufacturing process not only enhances the fabric’s physical properties but also streamlines production, making it a smart choice for industries looking for reliable and efficient packaging solutions. Whether for industrial goods requiring high-temperature handling or products needing robust packaging for transportation, Sealed Crush Fabric offers a compelling solution that marries durability with practicality.

Why Choose & Trust Simplex Chemopack

When it comes to selecting the best sealed crush fabric manufacturer, the decision should not be taken lightly. The choice significantly impacts the quality, durability, and effectiveness of the packaging solutions required by businesses across various sectors. Simplex Chemopack stands out as a leading manufacturer in this specialized field for several compelling reasons like Unparalleled expertise and innovation, Superior quality and durability, Environmentally friendly practices, Customer-Centric approach, and, Reliability and Trust.

Choosing Simplex Chemopack as your manufacturer for sealed crush fabric means partnering with a leader in the field. Our blend of expertise, quality, sustainability, customer focus, and reliability makes us the ideal choice for businesses seeking the best in packaging solutions. Trust us to deliver products that not only meet but exceed your expectations, driving your success in the competitive marketplace.

Call or email Simplex Chemopack Private Limited today to enquire or order the Sealed Crush Fabric Bags at +91 982 322 1119.