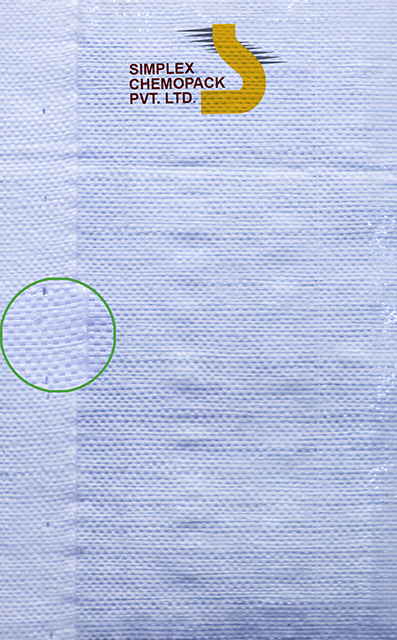

Prefold Autobond Fabric

In the era of packaging solutions, the innovation of Prefold Autobond Fabric marks a significant advancement. This fabric technology has been developed as a robust alternative to traditional materials, offering enhanced performance and efficiency in the creation of Flexible Intermediate Bulk Containers (FIBCs).

What is Prefold Autobond Fabric?

Prefold Autobond Fabric is a specialized form of polypropylene fabric, utilized in the production of big bags or FIBCs, which are essential for the storage and transportation of dry bulk materials. The fabric is produced either from flat woven or circular (tubular) polypropylene fabrics, which may be coated or uncoated. The result is a fabric optimized for both ease of use and long-lasting performance.

Features of Prefold Autobond Fabric

- Consistent, integrated strength: The thermal bonding ensures uniform strength throughout the material, eliminating potential weak points caused by stitching.

- Enhanced production efficiency: Prefold Autobond Fabric simplifies the sewing process, saving valuable time and reducing the risk of machine downtime.

- Uniform Strength: The application of heat along the fabric’s edges welds the thermoplastic components of the fibers together at their intersection points, ensuring consistent strength throughout the fabric.

- Enhanced Durability: By welding the fibers, the fabric achieves a bond that adds to its overall tensile strength, making it capable of handling heavy loads without compromise.

Advantages of Using Prefold Autobond Fabric

- Uncompromised product protection: The robust fabric and secure seams safeguard even heavy, demanding materials.

- Optimized FIBC construction: Streamline your manufacturing process for faster production and reduced labor costs.

- Reliable performance: Enjoy peace of mind with FIBCs that can withstand the rigors of handling, transportation, and storage.

Applications

Prefold Autobond Fabric is primarily used in the manufacturing of FIBCs for transporting and storing a wide range of dry bulk materials. Its robustness and durability make it an ideal choice for industries such as agriculture, construction, and pharmaceuticals, where the safe and efficient transport of goods is paramount.

- Bulk material handling: Ideal for cement, aggregates, fertilizers, grains, pharma products, and other dry materials.

- Demanding industrial applications: Well-suited to sectors requiring strong, dependable packaging.

Specifications to Consider

- GSM Range: Available from 130 GSM to 230 GSM, catering to various load requirements and specifications.

- Minimal edge tolerance: The fabric offers minimal tolerance, ranging from 0 to 5 mm, ensuring precision in manufacturing.

- Material: Polypropylene

- Process: Thermal edge bonding for reinforced selvages

Final Verdict

In conclusion, Prefold Autobond Fabric offers a transformative approach to FIBC manufacturing, combining strength, efficiency, and reliability in a single solution. With Simplex Chemopack, you’re choosing a partner that prioritizes quality and innovation, ensuring that your packaging needs are met and exceeded.

Why Trust Simplex Chemopack

Choosing Simplex Chemopack as your manufacturer for Prefold Autobond Fabric is a decision that comes with the assurance of quality, innovation, and reliability. Our success in finding a replacement for Sulzer with welded fabric technology underscores our commitment to delivering products that meet the highest standards of quality and effectiveness. Our process enhances the fabric’s strength but also simplifies the manufacturing workflow, notably reducing stitching time for weavers and increasing overall production efficiency. This focus on quality and efficiency is why Simplex Chemopack stands out as a premier choice for those seeking the best in pre-fold auto-bond fabric solutions.

Call or email Simplex Chemopack Private Limited today to enquire or order the Prefold Autobond Fabric bags at +91 982 322 1119.